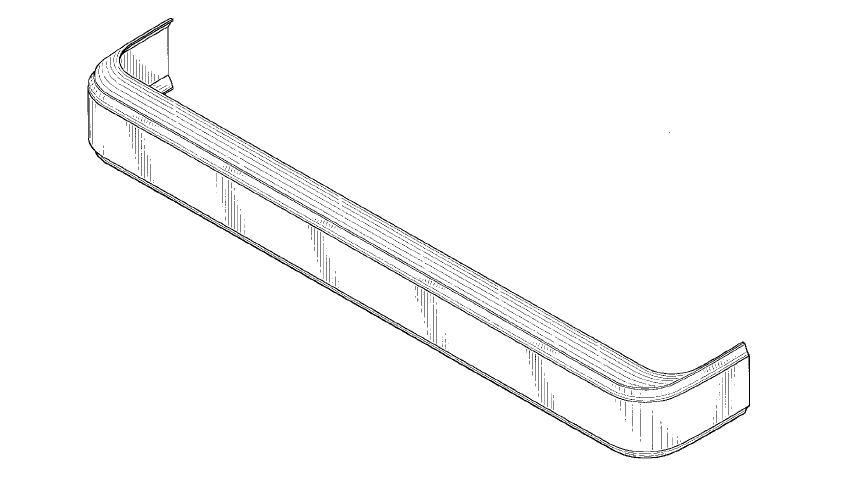

The HELP® Bumper Technology

At Romeo RIM, we utilize high-quality custom polyurethanes in the reaction injection molding process for our HELP® Bumpers (High Energy Level Polymer). As steel rusts, polyurethane remains bright and shiny and retains its original shape after years of exposure and impact. Romeo RIM offers in-mold priming and painting in our manufacturing process.

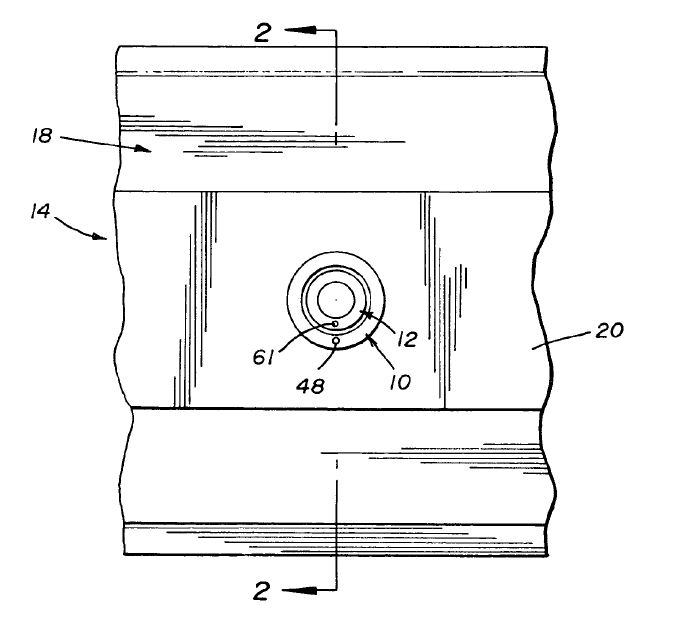

In-mold paint is sprayed onto the tool and chemically bonds with our custom polyurethane blend when injected into the mold. This produces a desired gloss and appearance our customers love while obtaining flexible properties to move with the bumper upon impact. With no cracks or chips, the paint remains where you’d expect it.

In-mold paint is sprayed onto the tool and chemically bonds with our custom polyurethane blend when injected into the mold. This produces a desired gloss and appearance our customers love while obtaining flexible properties to move with the bumper upon impact. With no cracks or chips, the paint remains where you’d expect it.

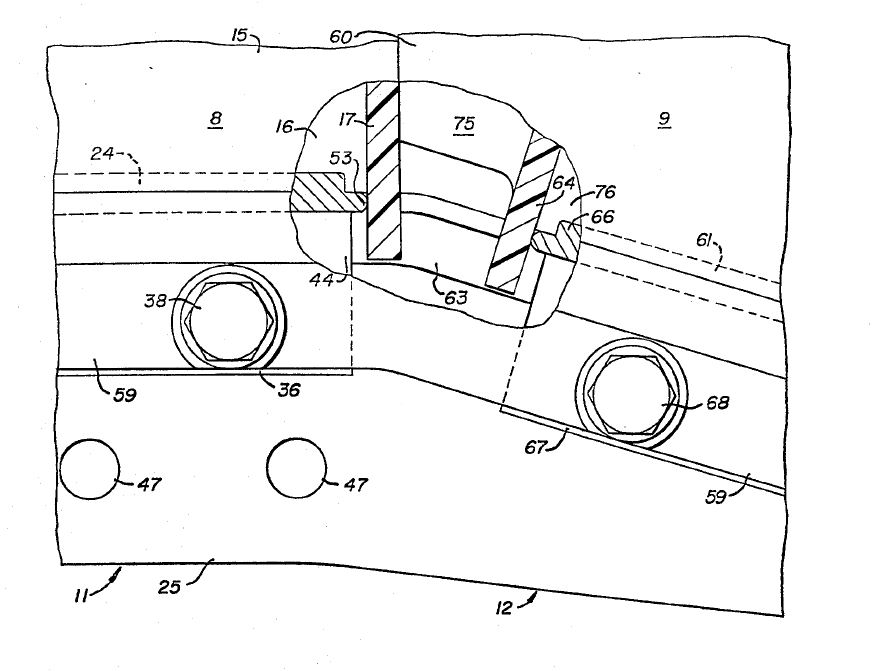

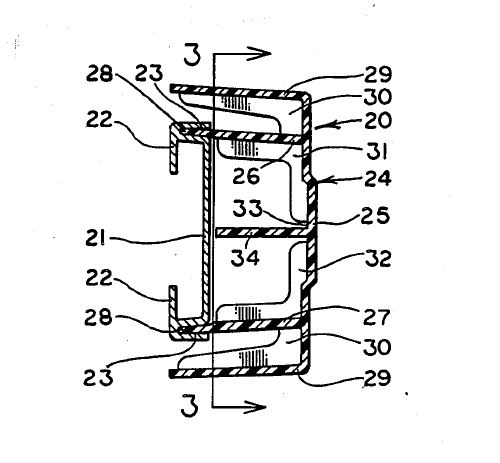

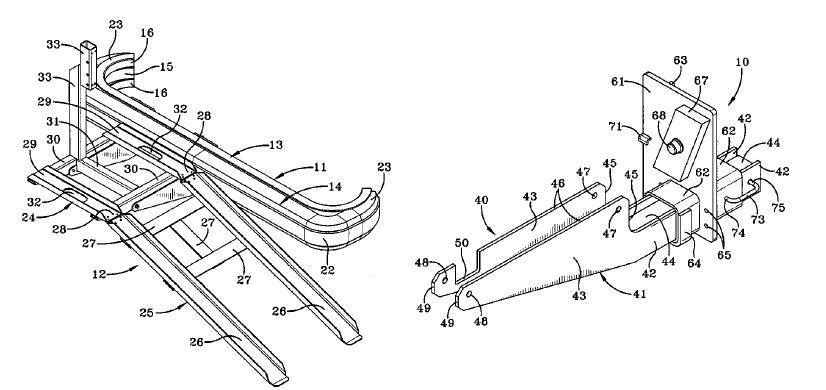

In addition to in-mold paint, we offer multiple back structure options. Our highly engineered aluminum back structures can include multiple features like mounting holes, fasteners for bike racks, and customized shapes upon the customer’s request.

We work with our customers to select a bumper system that meets their requirements for impact protection for vehicles from 5,000 pounds to 60,000 pounds. If we can't match one of our many existing products with our customers needs for performance, fit, mounting or aesthetic look, we will collaboratively work to create a new custom application just for them. We will work with the customers studio and engineering team to generate the "A" surface look desired while still providing the engineered performance in a package targeted to meet their cost, timing, and manufacturing needs.

The HELP® Bumper Performance

The HELP® bumper works actively to absorb energy from an impact and transmits the forces away from the vehicle chassis, shielding the vehicle from any harm. Unlike a steel or foam core bumper, the HELP® bumper can form back to its original molded shape without internally damaging the bumper, losing its energy absorbing properties and damaging the vehicle, even after multiple impacts. Our HELP® technology, combined with in-mold paint and an aluminum back structure, decreases downtime for your vehicle while saving you time and money that would otherwise be spent on maintenance and replacement parts.

HELP® Bumper System features:

- Reaction Injection Molding

- Energy Absorbing

- Puncture Resistant

- In-Mold Prime and Paint

- Withstands Multiple Impacts

- Styling Lines into the A-surface of the HELP® Bumper

- Multiple Back Structure Options

- Decreases Downtime

- Approved for 60,000 lb. Vehicles

- 1 -3 Bumper Modules with Breakaway Corners

- Meets APTA Bus Procurement Guidelines

Warranty

History

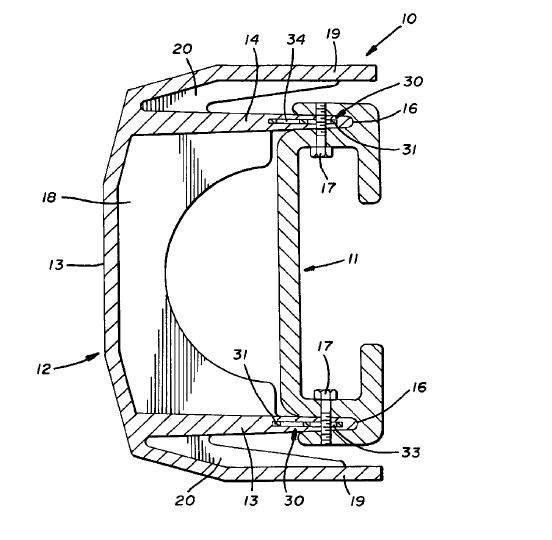

The HELP® Bumper is created by Romeo RIM, a complete composites solution company in Romeo, Michigan since 1982. The birthplace of Romeo RIM sits on the grounds of an old tire and rubber manufacturing company that used the reaction injection molding process also known as RIM. Using this same process technology, Romeo RIM was inspired to develop a RIM bumper that has similar energy absorbing properties as a tire, yet more durable and puncture resistant like a bumper. The patented and trademarked High Energy Level Polymer technology, otherwise known as HELP®, is a custom polyurethane blend that gives the bumper modules the mechanical properties to maximize the elastomer values which absorb energy. Romeo RIM continues to innovate while still using advanced tried and true materials proven in the industry.

The HELP® Bumper is created by Romeo RIM, a complete composites solution company in Romeo, Michigan since 1982. The birthplace of Romeo RIM sits on the grounds of an old tire and rubber manufacturing company that used the reaction injection molding process also known as RIM. Using this same process technology, Romeo RIM was inspired to develop a RIM bumper that has similar energy absorbing properties as a tire, yet more durable and puncture resistant like a bumper. The patented and trademarked High Energy Level Polymer technology, otherwise known as HELP®, is a custom polyurethane blend that gives the bumper modules the mechanical properties to maximize the elastomer values which absorb energy. Romeo RIM continues to innovate while still using advanced tried and true materials proven in the industry.

Patents